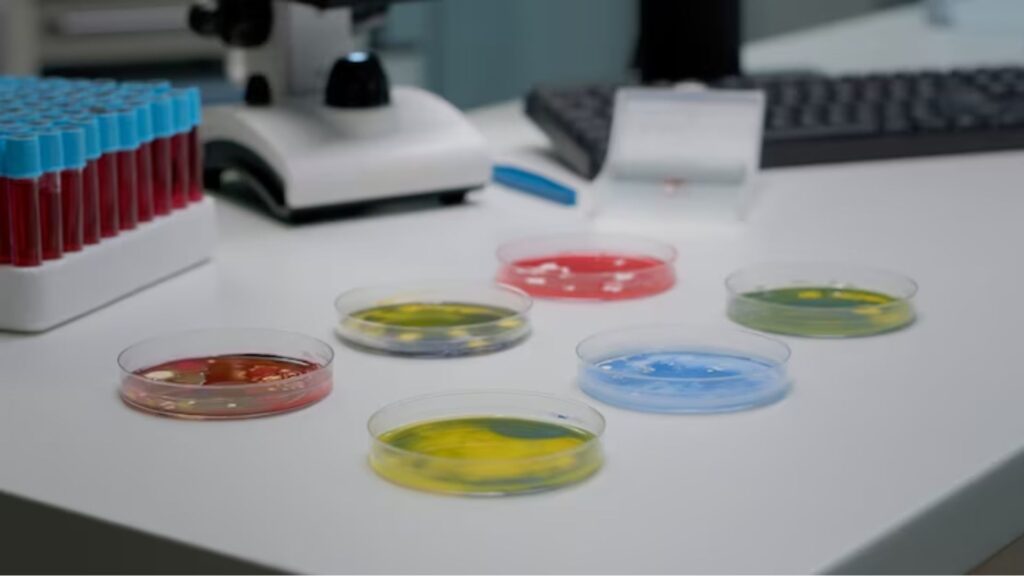

Raw material testing services are an important aspect of product development since they ensure that the materials utilized are safe, dependable, and of high quality. Raw material testing is used by companies in areas such as automotive, medical, and food and beverage to guarantee that their goods satisfy the highest requirements. Raw material testing labs in Dubai generally have a variety of testing devices and technologies used to assess the physical and chemical characteristics of raw materials. This aids in identifying possible issues that might result in product failure or health concerns.

Which industry requires raw material testing?

- At least one test must be performed by pharmaceutical producers to authenticate the identity of each vendor lot of raw materials used to create medicinal products. This involves microbiological testing and verification of active component purity, strength, and quality.

- Personal/Cosmetic Care Before using raw materials, manufacturers must test or inspect them for contamination with dirt, bacteria, or other foreign contaminants. The FDA anticipates at least one test to validate the vendor lot identification.

- Dietary Supplement Manufacturers must perform at least one test to confirm the identity of each vendor’s lot of raw materials used to make dietary supplement products. Before using a vendor lot, it must be examined for microbiological contamination.

Create a formal specification for each raw material.

The name, grade, physical, chemical, and microbiological attributes to be examined, as well as the test method and acceptance criteria, must be specified in writing. This is true across all sectors.

Create a Quality Management Programme for the Supply Chain.

A method for qualifying suppliers, confirming Certificates of Analysis, and a testing strategy should all be part of your supply chain quality control program. This is done to fulfill industry and organizational standards.

Which Raw Materials Does Qualitas Test?

Qualitas has extensive experience evaluating pharmaceutical and dietary supplement components, preservatives, botanical compounds, inactive ingredients, processing aids, solvents, and polymeric resins. The use of approved compendial methods or proven methods published in the peer-reviewed literature is recommended by Qualitas.

Qualitas’ Raw Material Testing Capabilities

To assure the quality and safety of raw materials used in products, Qualitas maintains cutting-edge Analytical Chemistry, Microbiology, Human Clinical, Photobiology, and In-Vitro Toxicology testing facilities. Qualitas is one of the most competent and experienced oil, gas, and drinking water testing labs in UAE. It guarantees that raw material analyses are carried out in strict conformity with the compendial, customer, or in-house techniques and that all applicable requirements are followed.

Testing methods Employed by Qualitas

There are several methods for testing raw materials. Depending on the item being analyzed, testing raw materials needs physical, chemical, and biological procedures.

- Physical testing evaluates the physical attributes of a material, such as its size, shape, strength, and durability. It is frequently used to assess metal and plastic strength, hardness, and other physical qualities.

- Chemical testing is used to examine a material’s chemical makeup to guarantee that it does not include harmful compounds such as heavy metals or poisonous substances.

- Biological testing determines a material’s safety by counting the number of germs or microbes present. This can aid in the identification of potential health hazards.

Conclusion

Raw material testing services are critical for producing safe, dependable, and high-quality goods. Businesses may assure client pleasure and safeguard their brand by ensuring that the materials used satisfy the highest standards. This is accomplished through the use of Qualitas Labs’ raw material, oil, and gas testing services in UAE.